Details

The principle of ORC power generation: The low boiling point liquid organic working fluid absorbs heat from a low-temperature heat source in the evaporator and evaporates into a higher pressure gas working fluid, which then drives the turbine expander to do work and rotates the generator to generate electricity. The working fluid that has done work in the turbine machine is exhausted and cooled back into a liquid in the condenser, then pumped back to the evaporator by the circulation pump to absorb heat and evaporate again, thus completing the cycle.

The ORC low-temperature waste heat generator set is suitable for hot water above 80°C, steam at absolute pressure of 0.1~0.6MPa, and flue gas above 180°C.

Schematic diagram of the principle

Skid-mounted ORC unit

Characteristics of ORC equipment:

● Product design does not require external oil separation and oil station systems;

● Modular design, highly integrated, with high system reliability;

● Unit design facilitates transportation and installation, with simple system operation;

● Factory testing reduces on-site debugging time.

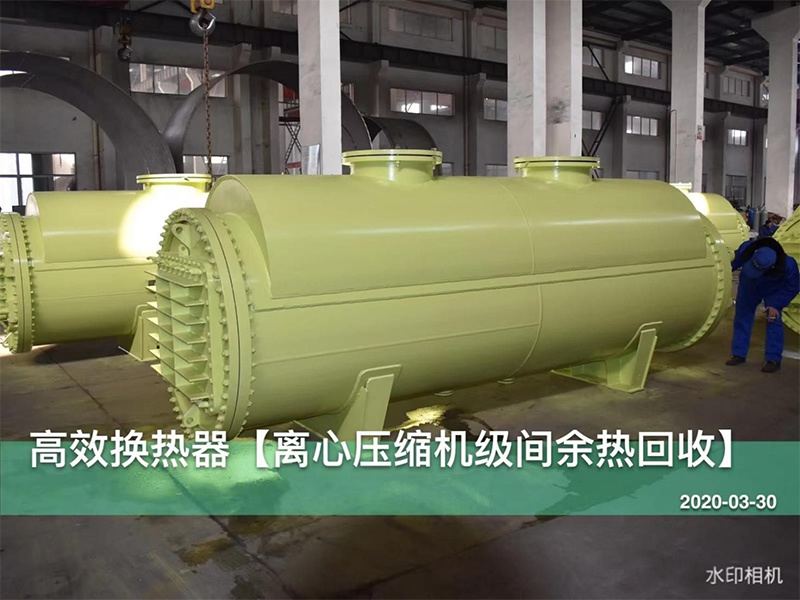

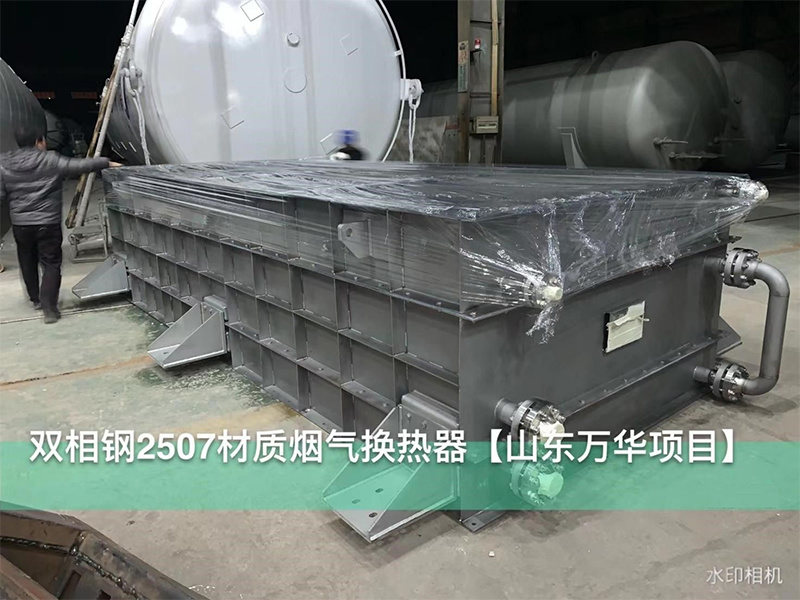

ORC project cases:

1. Waste heat recovery power generation project of a certain waste treatment plant

A certain waste treatment plant has three Caterpillar G3516 LE gas generators, which recover waste heat from the cylinder liner water. It can produce 106°C hot water to supply the ORC power generation system with 200KW/h. This saves a large amount of cooling water and reduces the energy consumption of the cooling tower. It improves the power generation efficiency of the gas generator set by 4%.

2. Low-temperature waste heat ORC power generation project of a certain chemical fiber plant

Recovering and utilizing the 102°C micro-pressure saturated polyester steam generated by the main process tower of the polyester production line, the total installed capacity of the project is 900kw. The electricity generated by this project is used entirely for the main equipment of the plant, saving 4.5 million kWh of electricity annually, saving 1,400 tons of standard coal per year, and reducing carbon dioxide emissions by 3,900 tons per year.

3. A certain geothermal power generation project

Currently, the pilot test project of CCUS in the Bailingxi Qianshan area has been advancing the preliminary work as planned. After the project is put into production, it will provide technical reserves for building a billion-ton-level carbon storage cluster in the Beijing-Tianjin-Hebei region. The Liubei geothermal power generation test project has built three 100-kilowatt geothermal generator sets, and after the test is completed, it can further promote high-temperature geothermal power generation, medium-temperature production heating, or low-temperature agricultural and pastoral tiered utilization. The lithium manganese oxide battery energy storage application test has been running smoothly for more than three months, accumulating experience for the next step of multi-energy complementary oilfield wind and solar storage and the promotion of new energy power supply applications. (Reporter Guo Wenfeng, Correspondent Dai Yue)

Excerpt from China Petroleum News http://news.cnpc.com.cn/system/2022/08/31/030078534.shtml

Refers to the technical system used to lower indoor temperatures and control humidity. It plays a very important role in modern society, especially during the hot summer months. The design and operating principles of cooling systems can be adjusted and optimized according to different needs and locations. The core of the cooling system is the refrigeration cycle, which includes key components such as the compressor, evaporator, condenser, and expansion valve. First, the compressor draws in low-temperature, low-pressure refrigerant and compresses it, raising its temperature and pressure. Next, the refrigerant enters the condenser, where it releases heat by coming into contact with outside air, turning into high-temperature, high-pressure gas. Then, the refrigerant passes through the expansion valve into the evaporator, where the refrigerant's temperature and pressure drop sharply due to the expansion valve's action, absorbing indoor heat and turning into low-temperature, low-pressure gas. Finally, the refrigerant re-enters the compressor, and the cycle continues. The advantages of cooling systems are not only reflected in lowering indoor temperatures but also in effectively controlling indoor humidity. Through the action of the evaporator, the cooling system can condense and discharge moisture from humid air, thereby reducing indoor humidity while providing a more comfortable environment. However, cooling systems also face some challenges and issues. First is the energy consumption problem; cooling systems require a large amount of electricity to operate, which can lead to high energy costs and environmental burdens. Secondly, the maintenance and upkeep of cooling systems also require certain investments and expertise to ensure the system operates normally and extends its lifespan. In summary, cooling systems are crucial in modern life. Through continuous technological innovation and optimization, we can further improve the energy efficiency and environmental performance of cooling systems, providing people with a more comfortable and healthy indoor environment.

Related Items

immediate consultation

We will contact you within one working day. Please pay attention to your email.

Customer Service Hotline

E-mail:wanglisheng@ahnyzb.cn

Telephone:0514-82079511

Fax: 0514-82079522

Company address: No.9, Nanhuan East Road, Dinghu Town, Jiangdu District, Yangzhou City, Jiangsu Province

Mobile Access

This website already supports IPV4 / IPV6 bidirectional access