12

2024

-

06

Waste Heat Recovery from Air Compressors

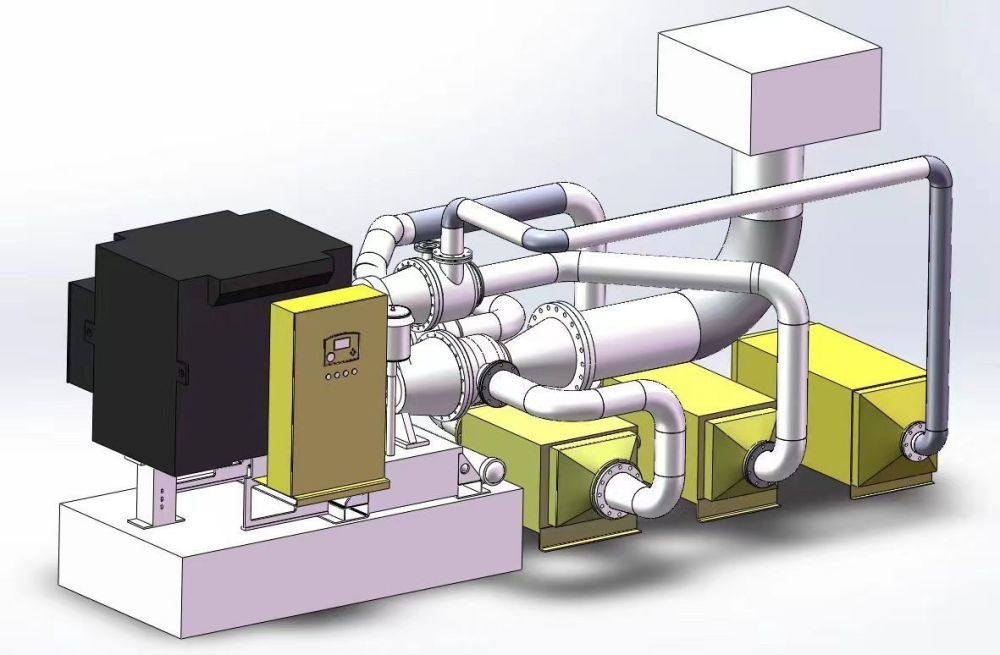

The compression heat generated by the air compressor accounts for about 80% of the energy input of the air compressor, resulting in a significant waste of energy. Taking a certain brand's SVK series air compressor as an example:

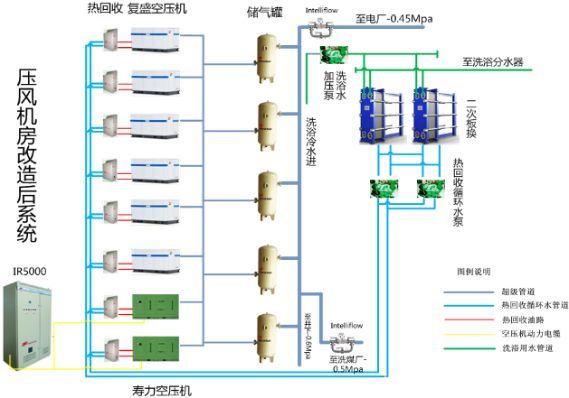

● Retrofit the waste heat recovery technology for multi-stage compression heat of centrifugal compressors to provide heat for enterprises, saving compressor operating costs; reduce the operating power consumption of cooling towers, saving water resources. It can provide hot water up to 90℃ for enterprise use.

| Centrifugal machine model | Annual recovered heat value (Kcal) | Can produce 80℃ hot water (t/h) | Annual energy-saving benefits (ten thousand yuan) |

| SVK160-3S | 27868362471 | 220.46 | 481 |

| SVK112-3S | 27961687365 | 220.25 | 482.9 |

| SVK6-4H | 10410382650 | 45.39 | 179.8 |

The above data is calculated based on full-load operation of the model for full-stage waste heat recovery, with a market price of 760 yuan/ton for 5500 kcal/kg thermal coal. Actual conditions are subject to on-site operation.

If this part of the heat energy is recovered, the heat energy can be used for...

● Showering

Number of people, number of shower heads, duration, shifts, any special requirements

● Process water/boiler make-up water

Water volume, water supply method, inlet and outlet water temperature difference, original heating method

● Heating

Heating area, temperature requirements

● ORC power generation (patented technology in the air compressor industry)

Water volume

● Lithium bromide refrigeration

Water volume

Utilize the recovered waste heat from air compressors for combined cooling, heating, and power design, achieving hierarchical utilization of heat sources according to user needs, improving utilization efficiency, with a maximum comprehensive utilization efficiency of over 70%.

Air compressor waste heat recovery project case:

1. A new waste heat recovery project in a pharmaceutical company

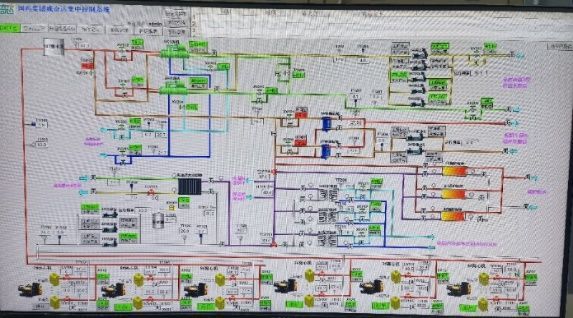

A subsidiary of China National Pharmaceutical Group has a total of 5 units of 857m³/min and 1 unit of 805m³/min air compressor systems. Through comprehensive design for heat recovery of the IR centrifugal machine, the recovered waste heat is applied for winter heating, summer cooling, and provides year-round boiler make-up water heating, cooling and dehumidifying air reheating, to achieve waste heat reuse, turning harm into benefit for energy saving and emission reduction.

Project results:

● Compressed air temperature throughout the year is 30±2℃

● Compressed air pressure dew point throughout the year is <-40℃

● Achieved boiler make-up water heating from 20℃ to 50℃ at 83t/h

● Achieved heating water heating from 50℃ to 75℃ at 226t/h

● Can produce 8-13℃ chilled water at 1600t/h

2. Phase I waste heat recovery project in a pharmaceutical company

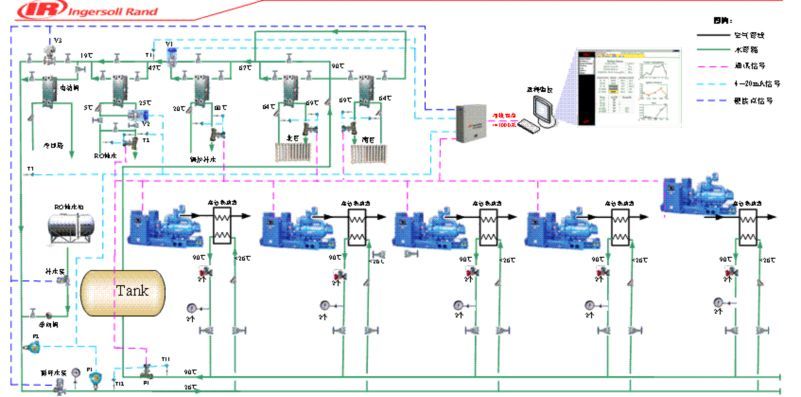

● This retrofit involves a total of 5 IR brand centrifugal air compressors.

● Successfully recovered the waste heat from the air compressor system and achieved reuse, resulting in an annual steam saving of 89,700 tons.

● Through a comprehensive system design, helped the client achieve reasonable allocation of waste heat resources at five application points for heating in two plants, preheating for wastewater treatment, preheating for boiler make-up water, and preheating for RO pure water.

3. Waste heat recovery project in a coal mine of Yanzhou Coal Mining Group.

Related Information

2023-08-10

2023-08-10

Customer Service Hotline

E-mail:wanglisheng@ahnyzb.cn

Telephone:0514-82079511

Fax: 0514-82079522

Company address: No.9, Nanhuan East Road, Dinghu Town, Jiangdu District, Yangzhou City, Jiangsu Province

Mobile Access

This website already supports IPV4 / IPV6 bidirectional access